Equipment Failures Are The Things Nightmares Are Made Of.

Equipment Failures Are The Things Nightmares Are Made Of.

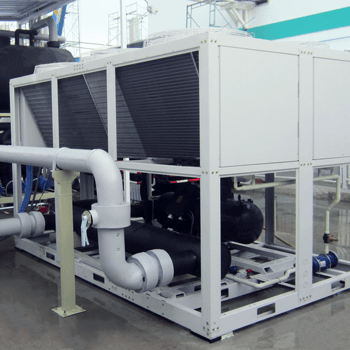

You have an industrial process that requires the use of either an air-cooled or a water-cooled chiller to cool equipment. Failure of this equipment or chillers has the potential to cost your business plenty as you lose valuable production time. Employees are left waiting with nothing to do, or performing non-income producing tasks to keep them occupied while waiting for failed equipment to be repaired.

Proper Maintenance Can Reduce Your Night Terrors

Many industries and processes use chillers as a part of their production process.

Industries:

- Manufacturing

- Data Centers

- Hospitals

- Hotels

- Campuses

Applications:

- Plastic Injection & Blow Molding

- Metal Working

- Welding

- Die Casting & Machine Tooling

- Chemical Processing

- Food & Beverage Processing

- Cement Processing

- Power Generation Stations

- Compressed Air & Gas Cooling

- MRI Machines

- Lasers

Whether your chiller is dedicated to a single process or piece of equipment or is used in a central location to serve multiple processes and equipment, regular maintenance is critical to the health of your production. Operating your chillers at peak performance will save energy and require fewer repairs. In short it will save you money.

Chiller maintenance has seen many advancements in technology. One such advancement is remote monitoring. This allows for a shift in available maintenance programs. You can either set up your maintenance as the traditional pre-sheduled maintenance or newer on demand maintenance schedule. If you don't know which is best for your needs, give AEM Mechanical Services Inc. a call. Their expertly trained and experienced team will help you determine your options.

During your chiller preventive maintenance check we will test, inspect and replace components. Typically this includes:

- Inspection of condenser heat exchangers

- Changing oil filters, refrigerant filters

- Oil change, if necessary

- Diagnostic tests on control panel and chiller starter

- Check wiring

- Lubrication to manufacture's specifications

Regular maintenance helps to lower operating costs, prevent costly break downs and Night Terrors.

Call AEM Mechanical Services, Inc., at 320-587-0991 and let's talk about your chiller maintenance program.